APG (Alkyl Polyglycoside)

What is APG?

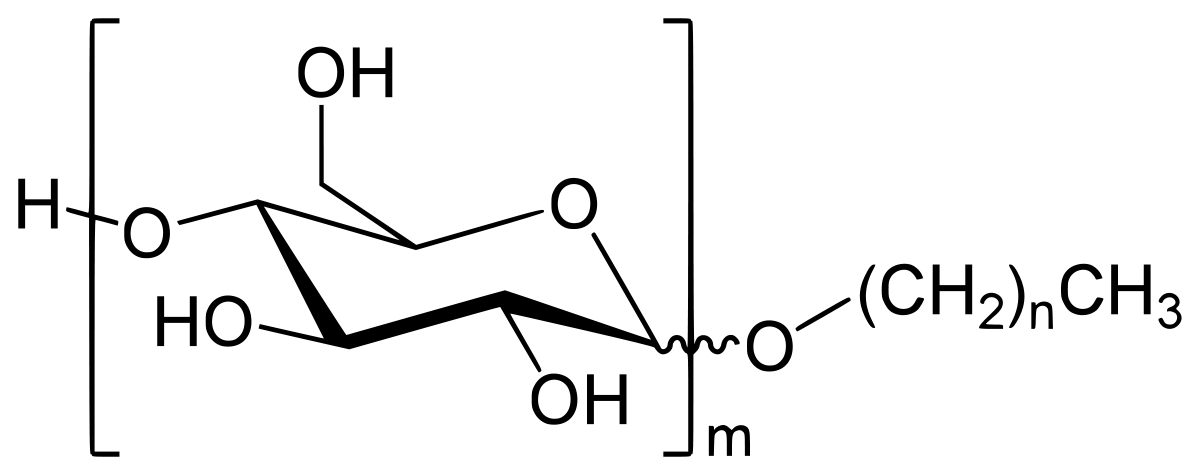

Alkyl Polyglucosides, often abbreviated as APG, are a class of non-ionic surfactants derived from renewable resources such as sugar and fatty alcohols. These biodegradable and eco-friendly surfactants have gained popularity in various industries due to their excellent cleaning and foaming properties. APGs are known for being gentle on the environment and are often used as alternatives to traditional surfactants derived from petrochemical sources.

Applications of APG

- Personal Care Products: APGs are commonly found in personal care items like shampoos, body washes, and facial cleansers. They provide gentle and effective cleansing while being less likely to cause skin irritation or allergies.

- Household Cleaning Products: APGs are key ingredients in eco-friendly household cleaning products such as dishwashing detergents, all-purpose cleaners, and laundry detergents. They offer excellent degreasing and dirt-removing capabilities.

- Industrial Cleaning: In industrial settings, APGs are used in various cleaning applications, including degreasing machinery, equipment cleaning, and as components in specialized cleaning formulations.

- Agriculture: APGs find applications in agriculture as wetting agents and adjuvants in pesticide and herbicide formulations, enhancing the effectiveness of these products.

- Oilfield Chemicals: In the oil and gas industry, APGs are used in drilling and completion fluids as emulsifiers and foaming agents.

APG: Benefits

The utility of Alkyl Polyglucosides can be attributed to several key advantages:

- Biodegradability: APGs are derived from renewable resources and are readily biodegradable, reducing their environmental impact.

- Low Toxicity: They are known for their low toxicity and minimal risk to human health, making them suitable for use in personal care products.

- Effectiveness: APGs offer effective cleaning and foaming properties, comparable to traditional surfactants, without the associated environmental concerns.

- Versatility: They are compatible with a wide range of other ingredients and can be used in various formulations.

How APG is Made

The production of APGs involves the following steps:

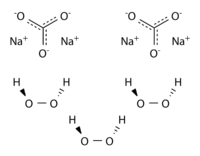

- Raw Materials: APGs are typically synthesized from two primary raw materials: glucose from cornstarch or other sources and fatty alcohols derived from coconut oil or palm kernel oil.

- Reaction: These raw materials undergo a chemical reaction, known as transglycosylation, where the glucose molecules are linked to the fatty alcohols to form alkyl polyglucosides.

- Purification: The resulting mixture is purified to remove impurities and unreacted starting materials.

- Formulation: The purified APGs are formulated into liquid or solid products suitable for various applications.

In conclusion, Alkyl Polyglucosides (APGs) are a sustainable and eco-friendly class of surfactants widely used in personal care products, household cleaning, agriculture, and industrial applications. Their biodegradability, low toxicity, and effective cleaning properties make them a preferred choice for industries and consumers seeking environmentally friendly alternatives to traditional surfactants. Understanding the benefits and production process of APGs underscores their significance in promoting sustainable and responsible use of cleaning agents and detergents.

Where can I buy APG (Alkyl Polyglycoside) in Europe ?

Contact us for APG (Alkyl Polyglycoside) availability and prices