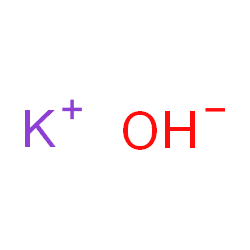

KOH flakes

What are KOH Flakes?

Potassium Hydroxide, often referred to as KOH, is an essential chemical compound with a multitude of applications across various industries. KOH is most commonly found in solid flake form, where it serves as a highly versatile and caustic substance. These flakes are the solid manifestation of potassium hydroxide, known for their purity and reactivity.

Applications of KOH Flakes

- Chemical Manufacturing: KOH flakes are a fundamental component in the production of numerous chemicals. They are used in the synthesis of potassium salts, soaps, detergents, and various organic chemicals. KOH is particularly crucial in the manufacture of potassium carbonate.

- Food Processing: In the food industry, KOH flakes are used for purposes such as pH regulation, peeling fruits and vegetables, and neutralizing acidic foods. It plays a vital role in processes involving cocoa and chocolate production.

- Biodiesel Production: KOH flakes are employed in the production of biodiesel as a catalyst for the transesterification of triglycerides into biodiesel fuel.

- Cleaning and Hygiene: KOH is used as a powerful cleaning agent. It can be found in various cleaning products and is effective in removing fats, oils, and grease.

- Pharmaceuticals: In the pharmaceutical industry, KOH is used as a reagent for various chemical processes and as a pH regulator in the formulation of medications.

KOH Flakes: Benefits

The use of KOH flakes offers several key benefits:

- High Purity: KOH flakes are known for their high purity, making them suitable for a wide range of applications where the quality of the chemical is essential.

- Strong Alkali: KOH is a strong alkali, and its flakes form an essential component in the production of caustic solutions used in numerous industrial processes.

- Versatility: KOH flakes are versatile and find use in diverse industries, from chemicals to food processing and pharmaceuticals.

- Effective pH Regulation: KOH is an effective pH regulator, ensuring precise control in various processes.

How KOH Flakes are Made

The production of KOH flakes involves several critical steps:

- Electrolysis: KOH is typically produced via the electrolysis of potassium chloride (KCl) brine. This process involves passing an electric current through a solution of KCl, leading to the formation of KOH.

- Crystallization: After electrolysis, the resulting KOH solution is concentrated and then allowed to cool. This causes KOH crystals to form.

- Flaking: The KOH crystals are then processed into flakes. This is achieved through controlled flaking processes that ensure uniformity and quality.

- Packaging: The KOH flakes are packaged into containers suitable for distribution and industrial use.

In conclusion, KOH flakes, derived from potassium hydroxide, are a versatile and crucial chemical compound with applications spanning various industries. Their high purity, strong alkaline properties, and effectiveness in pH regulation make them invaluable in chemical manufacturing, food processing, biodiesel production, cleaning products, pharmaceuticals, and beyond. Understanding the applications and production process of KOH flakes underscores their significance in diverse industrial sectors.

Where can I buy KOH flakes in Europe ?

Contact us for KOH flakes availability and prices