SMP (Soft Metal Powders)

What is SMP (Soft Metal Powders)?

Soft Metal Powders, abbreviated as SMP, represent a class of finely divided metallic particles characterized by their malleability and ductility. These powders are composed of metals with relatively low melting points, making them highly versatile for a wide range of industrial applications. SMPs are distinguished by their ability to deform and consolidate under relatively low pressures and temperatures, making them invaluable in various manufacturing processes.

Applications of SMP

- Sintering and Additive Manufacturing: SMPs play a crucial role in the field of additive manufacturing, commonly known as 3D printing. They are used as feedstock materials in selective laser sintering (SLS) and selective laser melting (SLM) processes to produce intricate metal parts and prototypes.

- Powder Metallurgy: In the realm of powder metallurgy, SMPs are employed to produce components with complex shapes and high precision. These components find applications in automotive, aerospace, and medical industries.

- Brazing: SMPs are utilized in brazing applications to join metal components together. The low melting point of these powders ensures a strong, reliable bond without compromising the integrity of the base materials.

- Thermal Spray Coatings: SMPs are used in thermal spray processes to create protective coatings on various surfaces. These coatings provide corrosion resistance, thermal insulation, and wear protection.

- Electronics: Soft metal powders are also used in the electronics industry for applications such as manufacturing conductive pastes, electronic packaging, soldering, and as a component in the production of electronic devices.

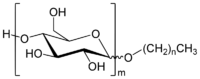

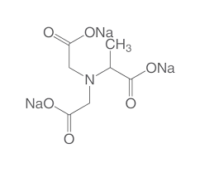

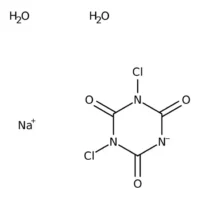

- Detergents: In the detergent industry, SMPs are employed as abrasive agents in cleaning products. Their soft, malleable nature makes them effective in removing stains and dirt from various surfaces without causing damage.

SMP: Benefits

The use of SMPs offers several key benefits:

- Low Melting Point: The low melting points of SMPs make them ideal for applications where high temperatures are undesirable or impractical. This property ensures minimal distortion of base materials.

- Versatility: SMPs can be tailored to specific alloy compositions, allowing for customization to meet precise application requirements.

- Intricate Designs: In additive manufacturing, SMPs enable the creation of intricate, complex, and highly detailed components that are otherwise challenging to manufacture using traditional methods.

- Cost-Effective: Powder metallurgy processes that utilize SMPs can be cost-effective due to reduced material wastage and energy consumption.

How SMP is Made

The production of SMP involves several key steps:

- Alloy Preparation: The desired metal alloy is carefully prepared by mixing the appropriate elemental powders in precise ratios.

- Atomization: The prepared alloy is melted and atomized to form fine droplets. Various techniques, such as gas atomization or water atomization, can be employed.

- Solidification: The atomized droplets rapidly solidify, forming spherical particles of SMP. The solidification process is carefully controlled to ensure the desired properties of the final product.

- Sizing and Classification: The resulting SMP particles are sized and classified to meet specific particle size distribution requirements.

- Quality Control: Stringent quality control measures are implemented to ensure the consistency and purity of the SMP product.

In conclusion, Soft Metal Powders (SMPs) are finely divided metallic particles with low melting points, making them invaluable in various industrial applications, including detergents. Their ability to deform and consolidate at relatively low temperatures and pressures is particularly advantageous in modern manufacturing, engineering, and cleaning products, among other fields. Understanding their production processes and benefits highlights their importance in a wide range of applications.

Where can I buy SMP (Soft Metal Powders) in Europe ?

Contact us for SMP (Soft Metal Powders) availability and prices