Polyvinyl alcohol

What is Polyvinyl Alcohol?

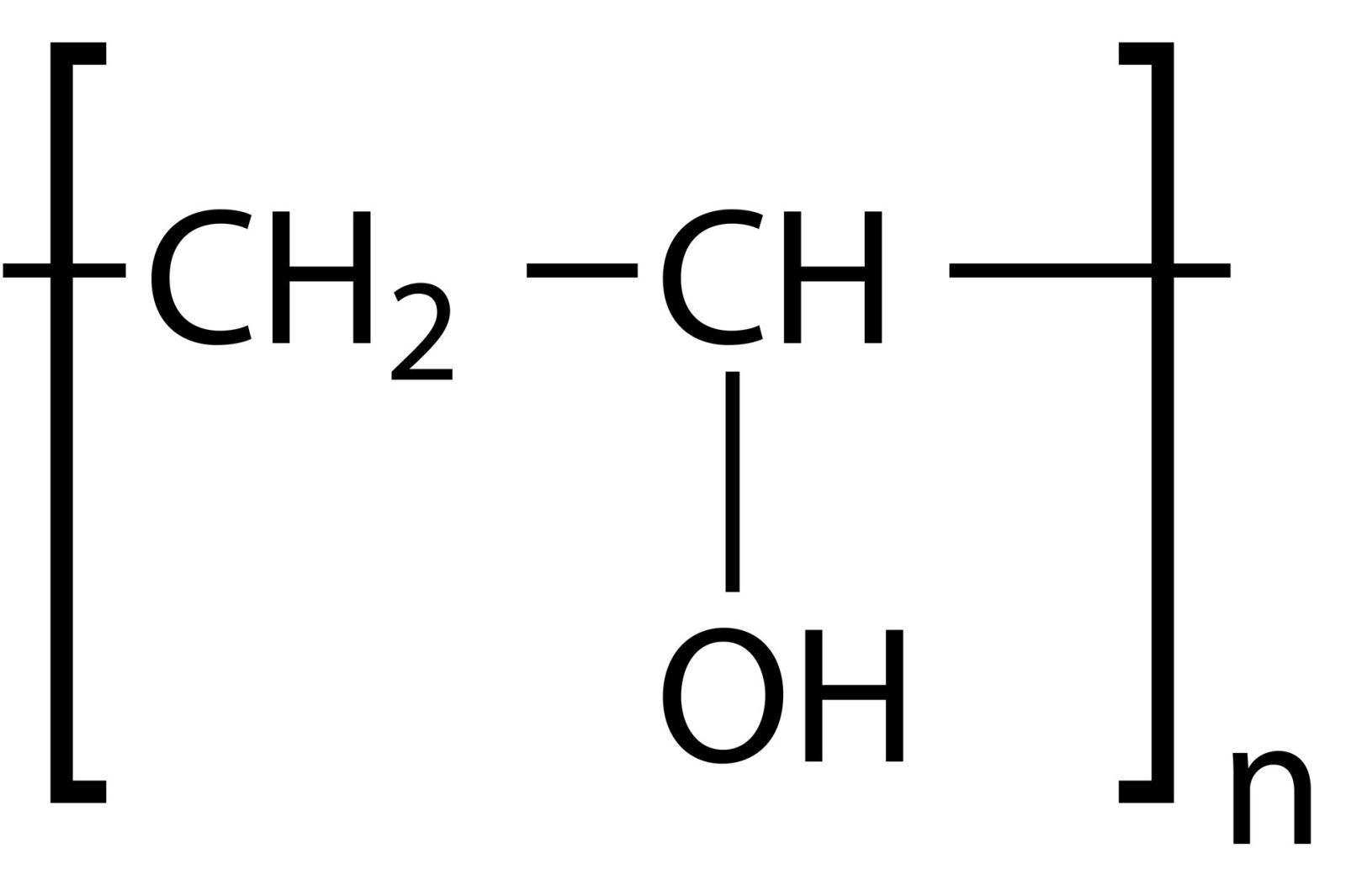

Polyvinyl Alcohol (PVA) is a synthetic polymer derived from polyvinyl acetate through a controlled hydrolysis process. It is a water-soluble, biodegradable, and non-toxic polymer that finds extensive use in various industries due to its unique properties. PVA is known for its film-forming capabilities and strong hydrogen bonding characteristics.

Applications of Polyvinyl Alcohol

- Adhesives and Glues: PVA is used in adhesives and glues for various applications, including woodworking, paper packaging, and craft projects. It provides strong bonding properties and is often preferred for its ease of use and non-toxic nature.

- Paper Industry: PVA is employed as a paper sizing agent to improve the strength and printability of paper products. It enhances the paper’s resistance to ink absorption and maintains its dimensional stability.

- Textiles: PVA is used in the textile industry as a warp sizing agent, providing a protective coating to yarns. This improves their weaving efficiency and reduces breakage during the weaving process.

- Construction: In the construction industry, PVA is used as a key component in the production of cement-based products, such as tile adhesives, mortars, and self-leveling compounds. It enhances the adhesion and workability of these materials.

- Emulsifiers: PVA serves as an emulsifying agent in the production of emulsions and suspensions. It stabilizes oil-in-water emulsions and is used in various industries, including pharmaceuticals and cosmetics.

Polyvinyl Alcohol: Benefits

The use of Polyvinyl Alcohol offers several key benefits:

- Biodegradability: PVA is biodegradable and does not contribute to long-term environmental pollution. It breaks down into harmless byproducts under the right conditions.

- Water Solubility: PVA dissolves readily in water, making it ideal for applications requiring water-soluble materials, such as dissolvable packaging films and laundry bags.

- Film Formation: PVA’s film-forming properties are valuable in applications like paper coatings and adhesives, where it creates a protective and adhesive layer.

- Non-Toxic: PVA is considered safe for use in various industries, including food packaging, textiles, and cosmetics, as it is non-toxic and does not pose health risks.

How Polyvinyl Alcohol is Made

The production of Polyvinyl Alcohol involves several key steps:

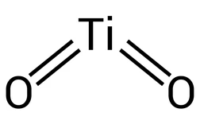

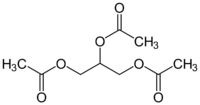

- Polymerization: The process begins with the polymerization of vinyl acetate monomers, typically initiated by a free-radical catalyst. This results in polyvinyl acetate, the precursor to PVA.

- Hydrolysis: Polyvinyl acetate is then hydrolyzed in the presence of an alkaline catalyst, such as sodium hydroxide, to break the acetate groups and replace them with hydroxyl groups. This hydrolysis step converts it into Polyvinyl Alcohol.

- Purification: The PVA is purified to remove impurities and unreacted materials, ensuring a high-quality product.

- Drying and Formulation: The purified PVA is dried and formulated into various grades, each tailored for specific applications. This can involve adjusting the degree of hydrolysis and the molecular weight of the PVA.

In conclusion, Polyvinyl Alcohol (PVA) is a versatile synthetic polymer widely used in adhesives, paper manufacturing, textiles, construction, and emulsions. Its unique combination of biodegradability, water solubility, film-forming properties, and non-toxicity makes it a preferred choice in a range of industries. Understanding its applications and production process underscores its significance in diverse industrial sectors and its contribution to environmentally friendly solutions.

Where can I buy Polyvinyl alcohol in Europe ?

Contact us for Polyvinyl alcohol availability and prices