ESBO (Epoxidized soybean oil)

What is ESBO?

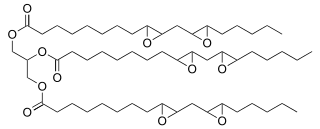

Epoxidized Soybean Oil, commonly known as ESBO, is a versatile chemical compound derived from soybean oil. It is a pale, viscous liquid that undergoes a unique chemical process called epoxidation, which imparts valuable properties to this substance. ESBO is valued for its various applications across different industries.

Applications of ESBO

- Plasticizers: ESBO is primarily used as a plasticizer in the manufacturing of flexible polyvinyl chloride (PVC) products. It improves the flexibility and durability of PVC items, making them more suitable for applications like wire and cable insulation, automotive interiors, and inflatable structures.

- Food Packaging: ESBO is often employed as a plasticizer and stabilizer in food packaging materials, such as cling films and food-grade PVC containers. Its non-toxic and food-safe properties make it a preferred choice for these applications.

- Medical Devices: ESBO is used in medical devices and pharmaceutical packaging, ensuring the flexibility and integrity of products like IV bags and blood bags.

- Coatings: ESBO is used as a coating agent in various industries, including automotive, where it provides adhesion and durability to coatings and paints.

- Adhesives: ESBO is employed as a plasticizer and tackifier in adhesive formulations, enhancing their adhesive properties.

ESBO: Benefits

The use of ESBO offers several key benefits:

- Plasticization: ESBO effectively plasticizes PVC and other polymers, improving their flexibility without compromising their structural integrity.

- Stability: ESBO imparts stability to PVC and other materials, making them less prone to degradation from heat, UV radiation, and chemical exposure.

- Non-Toxicity: ESBO is non-toxic and safe for use in food packaging, medical devices, and other applications where contact with humans is likely.

- Sustainability: ESBO is derived from renewable soybean oil, making it an environmentally friendly choice compared to some alternative plasticizers.

How ESBO is Made

The production of ESBO involves several key steps:

- Raw Materials: The primary raw material for ESBO production is soybean oil, which is abundant and renewable.

- Epoxidation: Soybean oil undergoes a chemical process called epoxidation, where double bonds in the oil’s molecular structure are converted into epoxide groups. This process is typically carried out using a peracetic acid or hydrogen peroxide catalyst.

- Purification: The epoxidized soybean oil is then purified to remove impurities and any residual catalysts, ensuring product quality.

- Formulation: The purified ESBO is formulated into the desired liquid form suitable for various industrial applications.

In conclusion, Epoxidized Soybean Oil (ESBO) is a valuable chemical compound with a wide range of applications in industries such as plastics, food packaging, medical devices, coatings, and adhesives. Its ability to improve the flexibility and stability of materials, along with its non-toxic and sustainable nature, makes it a preferred choice in numerous applications. Understanding its applications and production process highlights its significance in diverse industrial sectors.

Where can I buy ESBO (Epoxidized soybean oil) in Europe ?

Contact us for ESBO (Epoxidized soybean oil) availability and prices