TMP (Trimethylolpropane)

What is TMP?

Trimethylolpropane, commonly known as TMP, is a chemical compound with a wide range of applications in various industries. It is a triol, meaning it contains three hydroxyl (OH) groups, and it is derived from the condensation reaction of formaldehyde and isobutyraldehyde. TMP is a stable, white, crystalline solid at room temperature and is known for its versatility and usefulness in the synthesis of other chemicals.

Applications of TMP

- Coatings and Adhesives: TMP is a key ingredient in the production of alkyd resins, which are widely used in paints, varnishes, and coatings. These resins provide excellent durability, gloss, and adhesion properties to coatings.

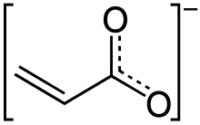

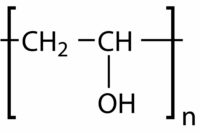

- Plasticizers: TMP is used as a plasticizer in the production of PVC (polyvinyl chloride) and other polymers. It improves the flexibility and workability of these materials, making them suitable for a wide range of applications, including cable insulation and automotive interiors.

- Lubricants: TMP is used in the production of synthetic lubricants and greases due to its excellent lubricity and oxidative stability. These lubricants find application in automotive engines and industrial machinery.

- Polyols: TMP serves as a building block for the synthesis of polyols, which are key components in the production of polyurethane foams, elastomers, and coatings. These materials are used in furniture, automotive interiors, and construction.

- Explosives: In the explosives industry, TMP is utilized as an ingredient in the production of certain explosive compounds, contributing to their stability and sensitivity.

TMP: Benefits

The use of TMP offers several key benefits:

- Versatility: TMP is a versatile compound that can be transformed into various derivatives, making it valuable in the synthesis of a wide range of products.

- Enhanced Properties: In coatings, adhesives, and plasticizers, TMP improves key properties such as adhesion, flexibility, and durability.

- Environmental Friendliness: TMP-based coatings and adhesives are often considered more environmentally friendly than alternatives due to their low volatile organic compound (VOC) content.

- High Lubricity: In lubricants, TMP contributes to reduced friction and wear, enhancing the efficiency and longevity of machinery.

How TMP is Made

The production of TMP involves several key steps:

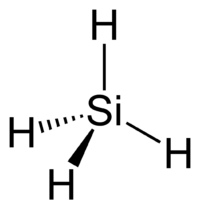

- Formaldehyde Production: Formaldehyde is typically produced from methanol using a catalytic oxidation process.

- Isobutyraldehyde Production: Isobutyraldehyde is synthesized from isobutene and formaldehyde through a catalytic process.

- TMP Synthesis: Formaldehyde and isobutyraldehyde are reacted together in the presence of catalysts to produce TMP. This reaction involves the condensation of three molecules of formaldehyde with one molecule of isobutyraldehyde.

- Purification: The crude TMP is purified to remove impurities and unreacted materials.

- Formulation: The purified TMP is formulated into the desired solid or liquid form for various applications. This can involve adjusting the degree of purity and physical properties of TMP.

In conclusion, trimethylolpropane (TMP) is a versatile chemical compound with a wide range of applications in coatings, adhesives, plasticizers, lubricants, and explosives. Its versatility and ability to enhance properties such as adhesion, flexibility, and lubricity make it a valuable ingredient in various industrial sectors. Understanding its applications and production process highlights its significance in enhancing the performance and functionality of a wide range of products.

Where can I buy TMP (Trimethylolpropane) in Europe ?

Contact us for TMP (Trimethylolpropane) availability and prices