DPM (Dipropyleenglycolmonomethylether)

What is DPM (Dipropylene Glycol Monomethyl Ether)?

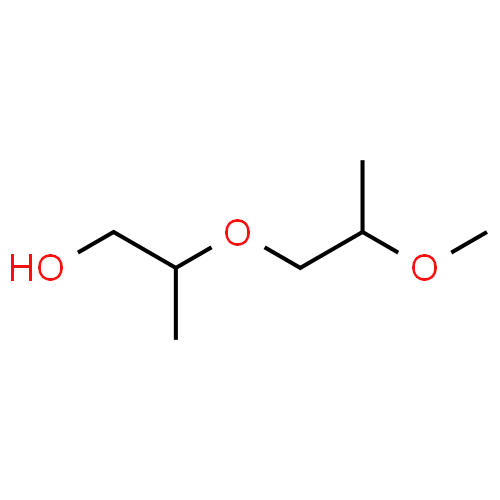

DPM, or Dipropylene Glycol Monomethyl Ether, is a colorless, low-viscosity liquid with a mild alcohol-like odor. Chemically, it is a glycol ether with the formula C7H16O3, consisting of a dipropylene glycol backbone with a methoxy (-OCH3) functional group. Its main characteristics include high solvency, low volatility, excellent miscibility with water and organic solvents, and chemical stability. DPM is important because it acts as an effective solvent, coalescing agent, and formulation enhancer, making it widely used in industrial, commercial, and personal care applications.

Applications of DPM (Dipropylene Glycol Monomethyl Ether)

DPM is utilized across various industries for its versatile properties:

Coatings and Paints: Serves as a solvent and coalescing agent, improving film formation, flow, and leveling of paints, varnishes, and inks.

Adhesives: Enhances solubility and flexibility, contributing to stronger bonding and consistent viscosity.

Textiles: Used in dyeing, printing, and finishing processes, ensuring uniform color application and fiber penetration.

Personal Care Products: Functions as a solvent and humectant in cosmetics, lotions, and fragrances, improving product stability and skin compatibility.

Industrial Cleaning Products: Acts as a solvent for oils, resins, and greases, increasing cleaning efficiency and surface wetting.

Benefits of DPM (Dipropylene Glycol Monomethyl Ether)

The key benefits of DPM include:

Excellent Solvency: Dissolves both water-soluble and oil-soluble components, enhancing formulation versatility.

Low Volatility: Reduces evaporation rate, ensuring longer working times and better performance.

Chemical Stability: Maintains durability and effectiveness in various environmental conditions.

Humectant Properties: Retains moisture in personal care products, enhancing skin feel and product efficacy.

Compatibility: Works well with a wide range of chemicals, making it suitable for diverse industrial applications.

How DPM (Dipropylene Glycol Monomethyl Ether) is Made

The production of DPM involves several key steps and raw materials:

Raw Materials: Primarily propylene oxide and methanol.

Synthesis: The materials undergo etherification reactions, forming the dipropylene glycol monomethyl ether structure.

Purification: The product is distilled and filtered to remove residual reactants and achieve high purity.

Formulation: Depending on application, DPM may be blended with other solvents or additives to optimize performance.

Special Technologies: Some manufacturers use catalytic processes to improve reaction efficiency, yield, and environmental sustainability.

Conclusion

DPM (Dipropylene Glycol Monomethyl Ether) is a versatile and valuable chemical that enhances the performance, durability, and functionality of products across industries. Its solvent power, chemical stability, and low volatility make it indispensable in coatings, adhesives, textiles, personal care, and cleaning applications, demonstrating its wide-ranging industrial significance.

Wo kann ich DPM (Dipropyleenglycolmonomethylether) in Europa kaufen?

Kontaktieren Sie uns für DPM (Dipropyleenglycolmonomethylether) Verfügbarkeit und Preise